ABOUT

A wide product range, a production capacity 18000 tpa, Top national and International Quality Awards. And an ISO 9001-2008 certification. Surely Lamina has every credential required of a leader. A forerunner among India's auto component manufacturers for the last 40 years, Lamina's claim to leadership lies in the hallowed sphere of quality and reliability. Because at Lamina, there's only one attribute worthy of a true leader - the ability to deliver impeccable quality time and again.

All reason why Lamina is a household name today. And why Lamina products continue to be trusted all over - be it in the competitive domestic markets or the uncompromising international markets of places as diverse as the USA, Brazil, Ecuador, France, Belgium, Germany, Italy, Sweden, Finland, U.K, Spain Holland, Middle East, Singapore, South Africa, Canada, New Zealand and Africa.

Lamina began its success story in the year 1976, with the setting up of Lamina Suspension Products Limited, a leaf spring manufacturer based in Mangaluru. Right from the beginning, Lamina's strength has been a clear understanding of one universal principle - that superior technique alone can guarantee product perfection. Indeed this belief has paid the company with rich dividends over the years.

In the year 2004, Lamina began manufacturing Parabolic Springs and Air links for Air Suspensions which find use in trucks, buses and other commercial vehicles.

Today, Lamina's extensive technological capabilities are matched only by its unflinching commitment to excellence. No wonder Lamina's manufacturing units are fully geared to meet the most rigorous of quality standards.

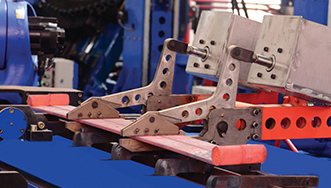

With a high degree of automation and extensive technological support, upgraded every year through in-house R&D facilities, they manufacture quality leaf springs that have withstood the toughest of Indian road conditions.

Complementing Lamina's product base is its fully automated foundry unit started near Mangaluru in 1983 with a production capacity of 15,000 tpa. It manufactures grey iron and alloy iron casting for industrial applications.

Lamina has come a long way. Now with the automobile scenario rapidly changing in India, with the advent of newer, more sophisticated vehicles by international manufacturers, the times ahead indeed seem exciting. For, Lamina has always thrived in facing challenges.

For challenge leads to innovation and innovation to better quality – a road quite familiar to Lamina.

Facilities

Facilities

Set up with a production capacity of 15,000 tpa, Lamina is fully equipped to produce high quality leaf springs to SAE and DIN specifications. Testing facilities at every stage of manufacture assure standards that are internationally accepted.

- Parabolic Rolling Machine

- Eye Rolling Machine

- Induction End Heating Furnace

- Heat Treatment Line

- Scragging and Load Testing

- Stress & Shot Peening Machine

- Painting Booth with Oven

- Fatigue Testing Machine

- Fully equipped Laboratory

AWARDS

AWARDS

The success of the unit is mainly due to the emphasis laid on the quality of the products by the management for which we were awarded "The National Award for Quality" in 1987 from the Government of India and "The International Gold Star for Quality" from BIDS, USA. The management decided to go in for ISO 9002 certification so as to ensure maximum emphasis not only on quality of the products but also on the quality of various systems and procedures. Today, it has been continuously certified for quality over the years. The company also recognized in the Supplier Summit 2008 for Outstanding Performance in the Logistics Sector.

Awards & Recognition